Employee Engagement

We invest in our people with opportunities for growth, collaboration, and a culture that values every voice.

YKK AP America Inc. is an innovation-driven manufacturer of commercial façade systems and residential windows and doors. Along with our subsidiary, ERIE Architectural Products, we support forward-thinking architecture through advanced manufacturing, sustainable design, and long-term value.

At YKK AP America, we turn architectural innovation into solutions that protect the environment, create value for our customers, and strengthen communities.

YKK’s founder, Tadao Yoshida made the “Cycle of Goodness” the central philosophy of all business activities.

At YKK AP, we design and manufacture high-quality fenestration solutions for both commercial and residential markets. See the types of products we offer.

Our products are used on buildings across the United States. Visit our project portfolio to see commercial projects featuring products from YKK AP and Erie AP.

The STUDIO 101 Design Center offers hands-on product demonstrations and training events. Featuring products from our commercial, residential and Erie AP businesses, we have locations in downtown Atlanta, GA and Rancho Cucamonga, CA.

YKK AP Inc. (Japan) is dedicated to building a better society through our Architectural Products (industrial products for construction), such as windows, doors, curtain walls, and exterior products.

At YKK AP and Erie AP, we believe a career should be more than just a job, it should be a path to growth, purpose, and possibility. When you join our team, you become part of a global company that values innovation, craftsmanship, and collaboration. Here, your ideas matter, your work makes an impact, and your future has no limits.

At YKK AP and EIRE AP, our people are the foundation of everything we build. Learn about some the team members who make innovation and excellence part of our everyday work.

We are looking for people who want to thrive in a collaborative culture and are motivated to do their best work. Our hiring process is the primary opportunity for us to get to know each other.

We believe in using business as a force for good. From sustainability to community involvement, we’re committed to making a positive difference.

As a leading building products manufacturer, we are committed to delivering long-term value to our employees, customers and communities.

Who We Are

YKK AP America Inc., the North American arm of the global YKK AP Inc. (Japan), is an innovation-driven manufacturer of commercial facade systems and residential windows and doors. Proudly made in the USA and Canada, our products support forward-thinking architecture through advanced manufacturing, sustainable design, and a commitment to exceptional customer experience.

We are committed to delivering long-term value to our employees, customers, and communities.

Our philosophy

At YKK AP, we believe prosperity comes from creating value that benefits everyone—our customers, partners, employees, and society. Guided by founder Tadao Yoshida’s philosophy that “no one prospers without rendering benefit to others,” we approach every decision and partnership with the goal of mutual benefit.

The Cycle of Goodness® remains the foundation of our work—driving innovation, sustainability, and shared progress.

Sustainability

True innovation goes hand-in-hand with environmental responsibility. At YKK AP, sustainability is integrated into every stage of our business—from responsible sourcing and transparent manufacturing to fair treatment of employees and delivering added value for our customers.

As part of the YKK AP Group’s Evolution 2030 global initiative and the YKK Group Environmental Vision 2050, we are actively working to reduce our carbon intensity and minimize our environmental footprint.

Manufacturing

From billet to finished product, YKK AP controls every stage of the manufacturing process. With ISO 14001-certified facilities in the U.S. and Canada, our fully integrated operations ensure consistent quality and performance.

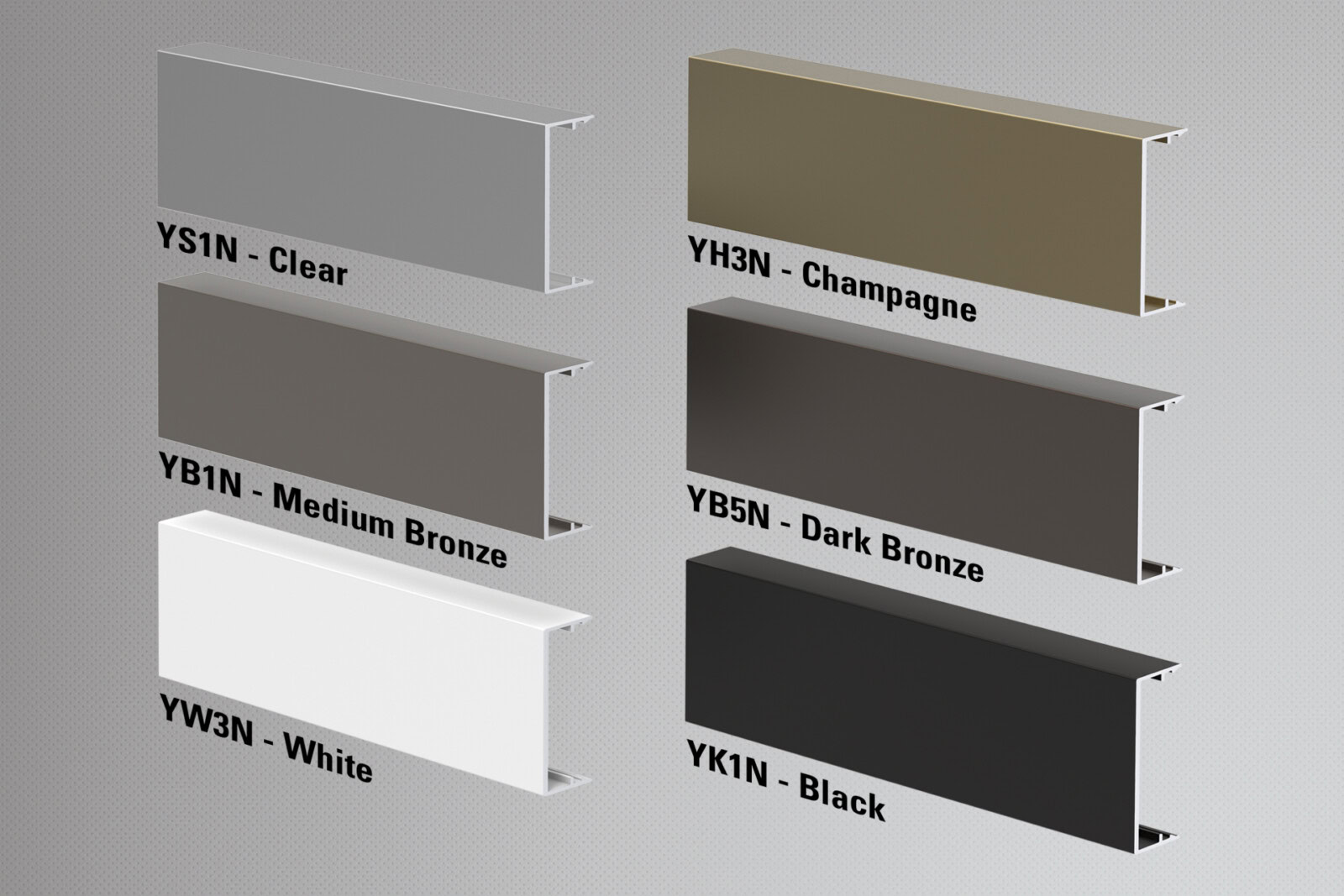

Unique to the industry, we produce our own aluminum billets, cut our own dies, operate multiple extrusion lines, and apply advanced anodizing, painting, and thermal break technologies—including one of the industry’s only vertical anodizing lines in the U.S. This level of control delivers precision-engineered products built for durability, performance, and sustainability.

Milestones that shaped who we are today

YKK AP introduced BetterBillet™, a proprietary aluminum billet made from recycled scrap and low-carbon primary aluminum, reinforcing the company’s commitment to sustainability. Produced in-house to ensure color consistency and material strength, BetterBillet is integrated into the majority of YKK AP’s commercial products.

To support growing demand in the Western U.S., YKK AP invested in expanded resources and personnel, establishing the Los Angeles Sales and Manufacturing Center in Rancho Cucamonga, California. The location also added engineering support to enhance regional service and responsiveness.

The 400,000-square-foot, purpose-built greenfield facility manufactures residential windows and doors for homebuilders and homeowners throughout the Southeast. By integrating vinyl extrusion, fabrication, and glazing under one roof, the facility improves operational efficiency and capacity through a strategic layout and investment in new equipment. Designed with employees in mind, the facility also features climate control, increased natural light, and outdoor amenities including a walking trail and basketball/pickleball court.

Tim Thomas, formerly SVP of sales operations, was promoted to President of Erie Architectural Products. In this position, he will leverage his more than 38 years in the glass and glazing industry to lead Erie AP into its next phase of growth.

We opened a new showroom—later dubbed STUDIO 101, in our downtown Atlanta HQ facility, offering customers and architects the opportunity to view, demo and learn about our residential and commercial products. This location also houses corporate staff, engineering and a training center.

Our second regional manufacturing center in Cincinnati, Ohio was opened in 2019 to improve the company’s service capabilities for customers in the Midwest region. The over 100,000 square foot space enabled us to increase YKK AP’s local production capabilities and allow for more finished goods inventory.

Pearson’s career with YKK AP has come a long way since starting as a receptionist through a temp agency to becoming one of the company’s most admired sales representatives. After a successful year excelling amongst her peers, she became the first ever female recipient of the company’s coveted President’s Award which is awarded annually to a top performing sales representative.

In 2019, we made the strategic move to acquire high-performance facades solution provider, Erie Architectural Products in effort to grow our offering for prefabricated, pre-assembled products. By bringing Erie AP under the YKK AP umbrella, we made a progressive move to meet a growing market demand for unitized products while helping to enhance Erie AP’s position and reach in the market.

In 2018, our first female vice president was appointed. Patrys brought decades of experience to a newly created organizational excellence department responsible for moving our company forward in the areas of employee engagement, talent acquisition and human capital technology.

In 2017, we led a challenge for local businesses to help complete Martin Luther King, Jr. Monument Park in Dublin, GA – marking the place where 15-year-old Martin Luther King, Jr. gave his first public speech in 1944. With commitment to diversity at the forefront, our president Oliver Stepe was inspired to make YKK AP one of the few manufacturers to recognize Martin Luther King, Jr. Day as a paid company holiday.

In 2016, Oliver Stepe, then SVP of Sales, was promoted to President of YKK AP America Inc., ushering in new initiatives and cultural changes while preserving the values of the YKK AP group. Joining YKK AP in 1992, he has grown with the company and experienced many roles along the way. In his first year, Oliver appointed the company’s first minority director and led business expansion to the west coast.

In 2015, we became the first manufacturer in the fenestration industry to obtain third-party certified environmental product declarations for our entire product portfolio. This meant that we could now offer seven certified categories of architectural products to meet LEED v4 requirements, underscoring our continued commitment to sustainability.

In direct response to feedback collected in our “Voice of the Customer” survey, we launched the direct freight program in 2015 to ensure our customers’ orders are handled with the utmost care. This program which services routes coast-to-coast reduces damage and increases scheduling predictability for our commercial customers.

In July 2014, we opened the doors to our first regional manufacturing facility in Coppell, Texas. The 105,000 square foot facility was pivotal in increasing local production capability and allowing for expanded finished goods inventory. The facility now serves as a key supply and distribution center, providing services to the entire south central and western regions.

In 2013, at AIA Denver, we debuted the first “I am an Architect” video – a parody about the challenges an architect typically faces in daily life. The fun video starred “architects” Brady and Mosby who have amassed their own fans as the series spawned another six videos. Today the video series has two million views and was the foundation for building an AEC Facebook community of over 64 thousand people.

We hosted our first “Chillin’ with YKK AP” event at the minus 5° ice lounge in Las Vegas. This brought customers, employees and industry partners together for an evening of fun, relaxation and entertainment with a goal of building deeper relationships with our customers and industry partners.

In 2011, we got creative at AIA New Orleans by teaming up with New Orleans Baby Cakes’ (then known as the Zephyrs) starting pitcher Trey Shields to demo the strength of its ProTek® line of impact resistant glazing systems. Shields took his best shot, throwing several pitches at the window system at an estimated 80 mph to illustrate the impact-resistant qualities of our products.

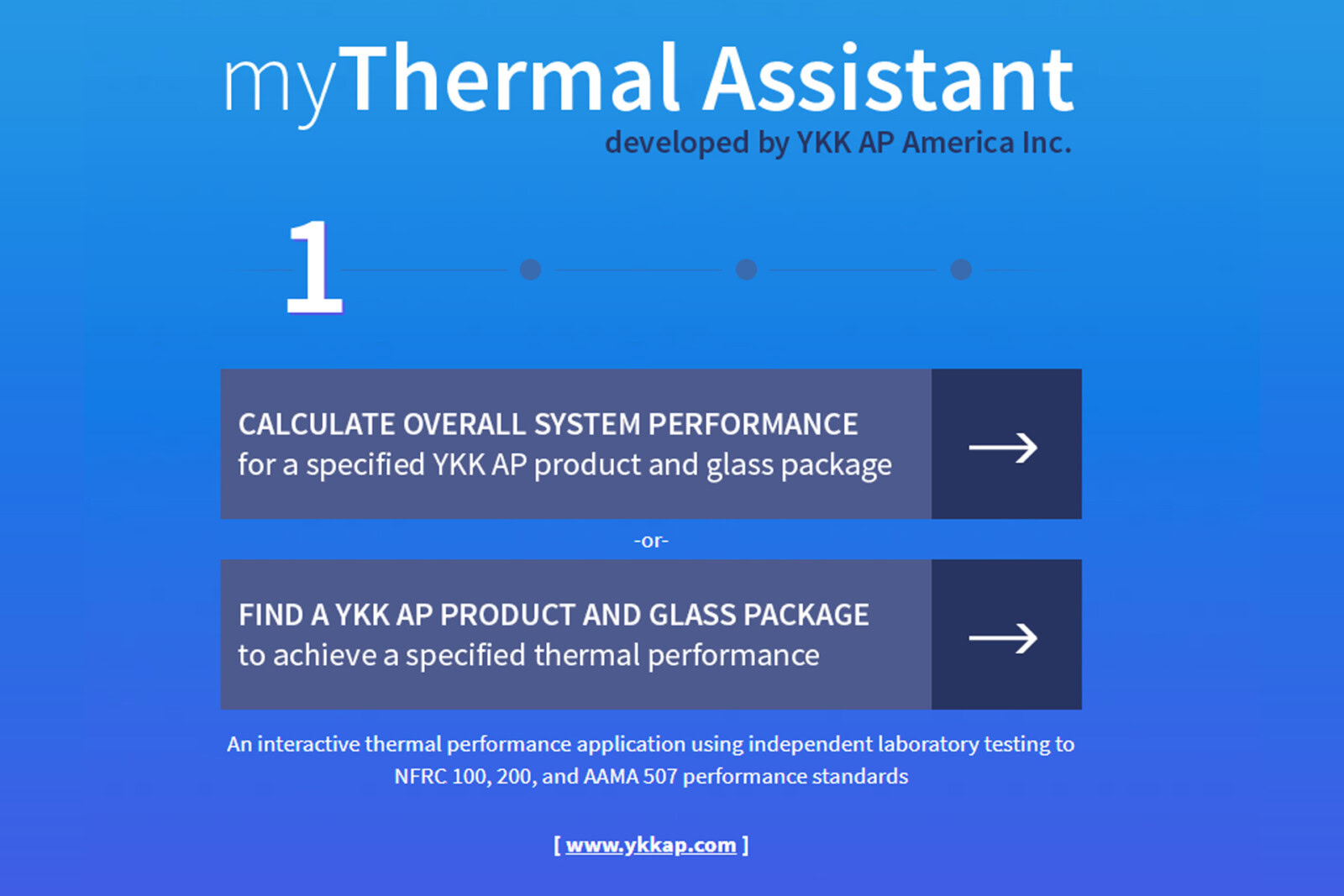

In 2010, we debuted our thermal performance calculator, myThermalAssistant. This tool enables building professionals to calculate the energy saving performance metrics of YKK AP products with project-specific glass packages using the AAMA 507 standard based on NFRC methods. This launch represented the first time users were able to calculate overall façade U-factors in seconds.

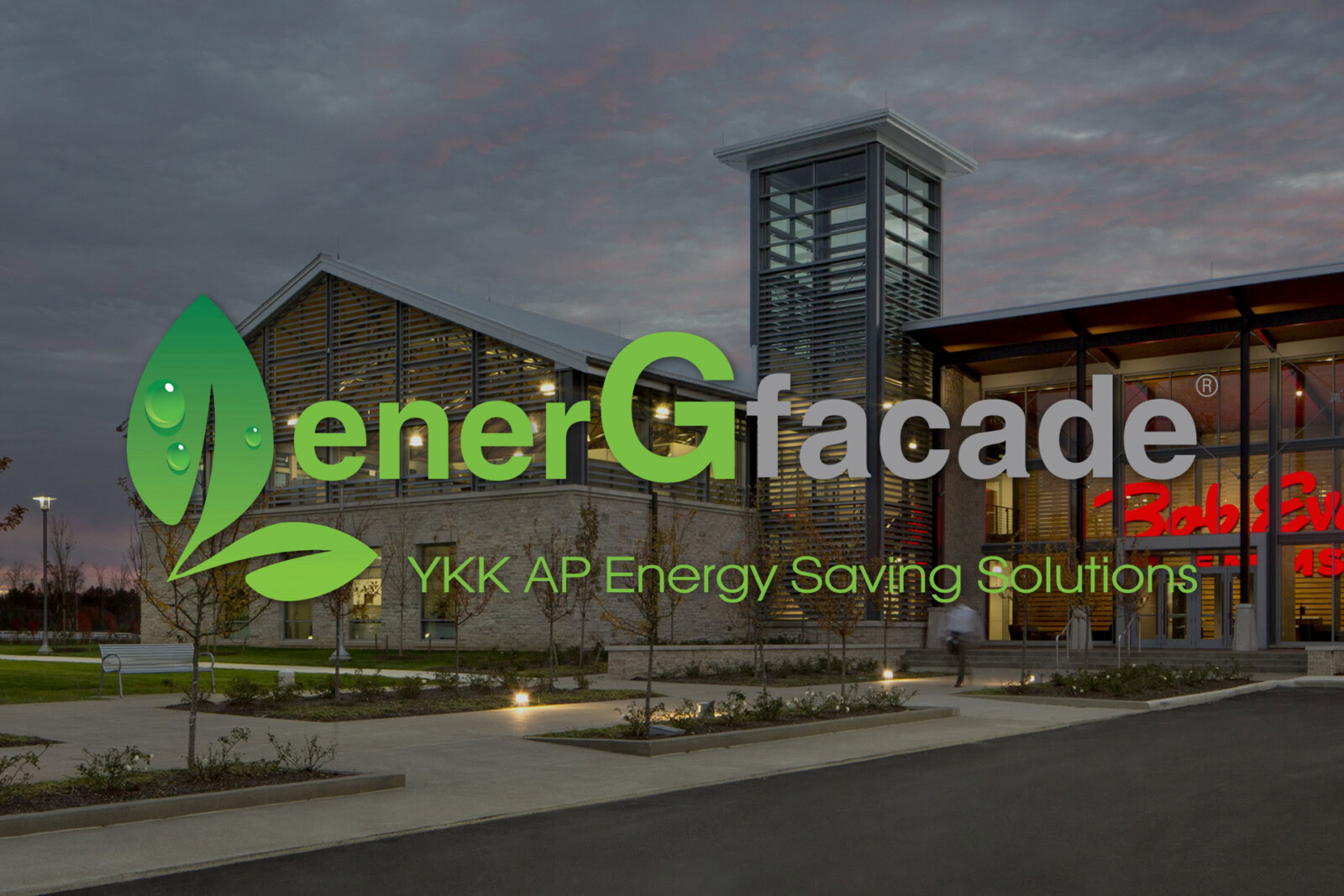

In 2009, we became the first manufacturer in the industry to launch an energy-efficient line of framing systems under the brand name enerGfacade. enerGfacade systems use patented technologies to offer advanced thermal performance that meet evolving building code and green standards.

2008 marked the launch of the ThermaShade® Sun Control system, which has since won numerous awards including the IDEA design award in 2009. ThermaShade integrates with our most popular wall systems and offers countless design options. One key selling point of ThermaShade is the ease-of-installation with a hanger bolt and slotted receptor design.

What started as a project became an official business group in 2007, as we diversified into another market. This year, we also began plans for a vinyl window manufacturing facility in Macon, GA, where the hub of our residential business still remains.

2006 saw the groundbreaking ceremony for phase 1 of an $80M expansion of our Dublin plant. This investment opened nearly 200 jobs for the local community. That same year, YKK AP was named one of the industry’s top ten employers by US Glass Magazine.

In 2005, we officially entered the residential market with the first shipment of vinyl windows delivered to Quality Craft, Inc.

In 2004, YKK AP achieved $100 million in sales for the first time. We continue to seek improvement in products and processes in order to keep growing and add value to our employees, customers and and communities.

Our Dublin commercial manufacturing plant was ISO 14001 certified, a standard which reduces the environmental footprint of a business as well as decreases the pollution and waste a business produces. The plant continues operating to these high standards today with a 73% recycling rate.

In 2002, we held the grand opening for our new fabrication plant, located next to the manufacturing plant in Dublin. This expansion allowed us to increase capacity for commercial entrances and expand our portfolio of commercial windows.

In 2001, in an effort to expand our footprint within the AEC community, we began attending national trade shows starting with the NGA show (now known as Glassbuild). Today, we attend or sponsor several select events each year, and we are frequently a standout at the AIA Conference. Our booth was awarded Best In Show in 2015.

In 2000, we were awarded the Region 9 Existing Industry Award by the Georgia Economic Developers Association for “exceptional contributions made to its community and the state.” Over the years, we have received numerous awards for our community initiatives, industry engagement and product innovation.

In 1999, we released the first version of our Ycalc® estimating software. Since then, the tool has progressed into what is known today as Ycalc® X5 powered by Logikal®. YCalc® X5 helps glazing contractors with preliminary structural design, shop drawings, material optimization/take-offs, and fabrication utilities.

In 1998, we worked with the City of Dublin, GA to establish the “Sister Cities” relationship and annual student exchange program between Dublin and Osaki Japan, a program that is still active today. This is one of several programs and community initiatives in which we lend our support, including the Dublin FIRST Robotics Competition, local river clean ups, AEC Cares and hometown AIA initiatives.

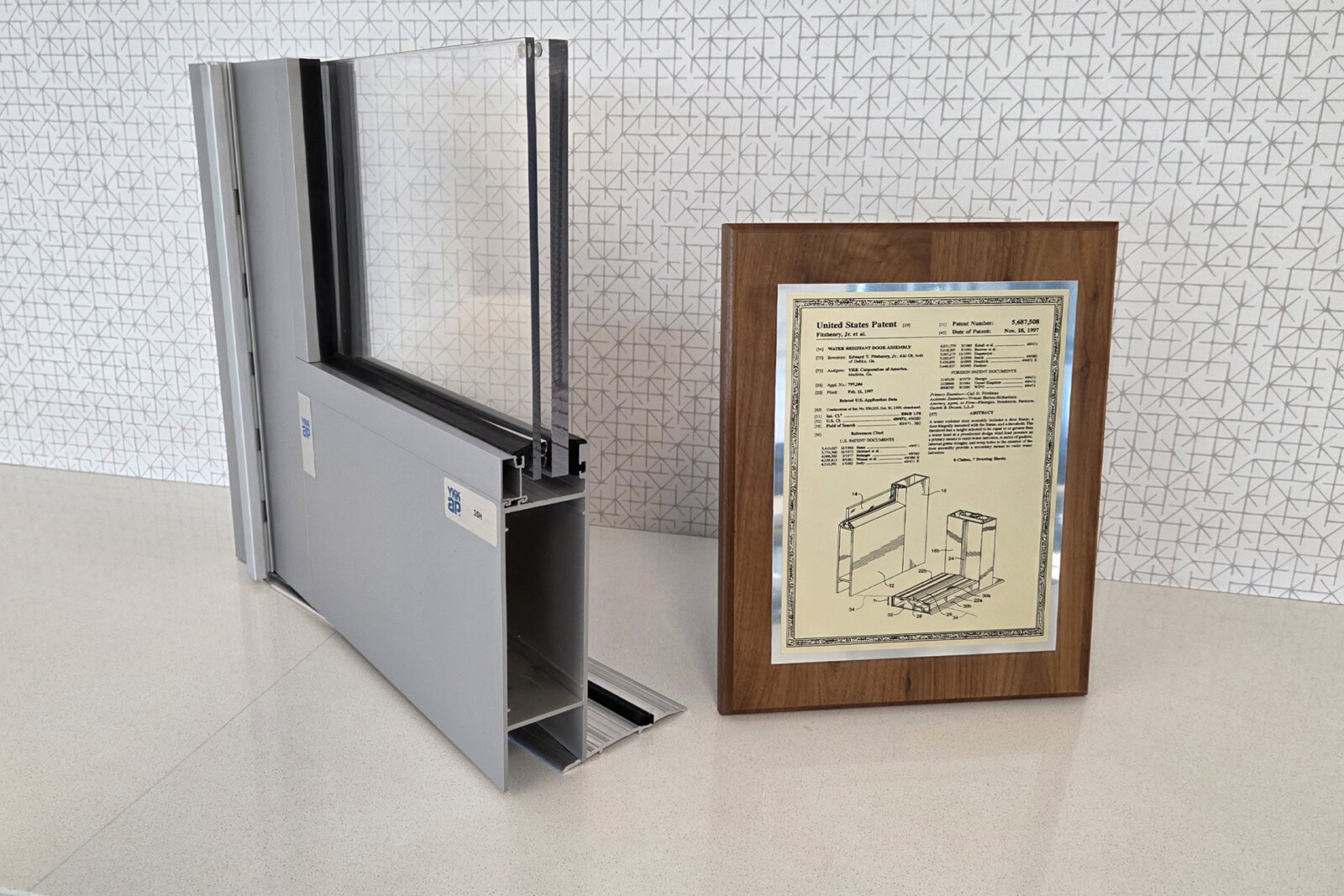

1n 1997, we were granted a patent on our top-selling ProTek® entrance design for its ability to effectively resist water as part of an integrated framing system; this design was pivotal in ProTek’s® rise as a top impact-resistant solution in the market today. We have continued to innovate, collecting several patents, including features of our StyleView® residential window sash and commercial aluminum ThermaShade® Sunshades.

In 1996, we opened the doors to our Cincinnati branch, the sixth of our satellite locations. This continued our commitment to provide strong local service and support our communities. Today, we have ten branches that serve architects and customers from coast-to-coast. In this year, we also expanded the Dublin manufacturing facility by 100,000 square feet.

In 1995, we launched a team known as the “Project Center,” which was dedicated to supporting medium to large-scale projects. Today, the Project Center takes on larger projects with unique challenges, providing value-added services such as estimating, engineering and project management.

Following the destruction in the Southeast caused by hurricane Andrew, we became the first aluminum façade manufacturer to develop a complete, integrated entrance and framing solution for impact resistance, ProTek®. Ten years later, we expanded the line into blast mitigation to address protection from environmental and security events.

We employ a unique vertical anodizing process called Anodized Plus®. Aluminum profiles are anodized and then receive an organic seal that is electrodeposited and sealed into the aluminum pores for enhanced durability. Anodized Plus remains the industry’s only high performance anodic finish that meets the more stringent AAMA 612 standards.

We opened our manufacturing plant in Dublin, GA in September 1992. The heartbeat of our company, our manufacturing facility is an impressive, vertically integrated operation with unique technology that allows the complete process, from melting and casting of aluminum to die manufacturing, extrusion, finishing, and fabrication to shipping.

We entered the market with aluminum products made by YKK AP Japan in 1984 and opened a branch in Atlanta in 1986. With interest in establishing a significant presence in the USA, YKK AP America Inc. was incorporated on April 24, 1991. The company chose Dublin, GA as home for its manufacturing base.

We invest in our people with opportunities for growth, collaboration, and a culture that values every voice.

We take pride in supporting the communities where we live and work, giving back through service, partnerships, and local engagement.

Our 25 Fundamental Behaviors outline the everyday actions each of us can take to bring our culture to life— guiding how we work, lead, and succeed.

High-performance aluminum facade, window, and door systems for a wide range of commercial building applications. Supported by design tools, technical expertise, and responsive service to help architects and glaziers move projects forward with confidence.

Premium residential windows and patio doors designed for durability, efficiency, and everyday comfort. Serving the Southeastern U.S. through a trusted dealer network, supporting homebuilders, homeowners, and residential architects.

A specialized commercial business delivering custom unitized curtain wall solutions for complex, large-scale projects. Through its ENVIRO|FACADES® line, Erie combines design assist, performance testing, and advanced manufacturing to support demanding architectural applications as part of the YKK AP family.